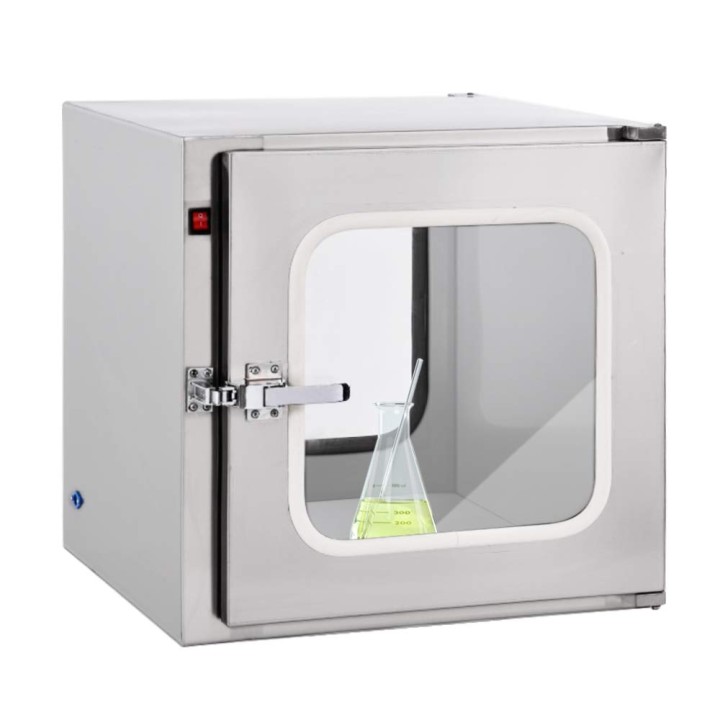

Acidum-inhibentes et Antioxidant capabilities de immaculatam ferro Cleanroom fores clavis attributa cursus stabilitatem salutem tanroom environments et manifesta multiplicibus ut sequitur;

I. Intrinsic materia proprietatibus naturalis tutela ex eget inertness

Chemica obice effectus summus chromium passive films

Chromium (Cr) elements in stainless steel (e.g., 18% Cr in 304 stainless steel, 16%-18% Cr in 316L stainless steel) spontaneously form a dense chromium oxide (Cr₂O₃) passive film approximately 1-3 nanometers thick upon contact with air or oxygen-containing media. Haec film exhibet eximia chemical stabilitatem, effective isolating acidic, alkaline, et SAL MARRERSIVUS MEDIA a recta contactus cum metallum subiecta. Nam exempli gratia, in X% hydrochloric acidum solution, in rate rate of CCCIV immaculatam ferro est infra 0,1 mm / anno, cum etiam ex II% -3 Molybdat (E.G.) in chloride -3 endirment (E.G.) in chloride -3 (E.G., maritimam, acidic wastewater ad (per L% comparari ad CCCIV immaculata ferro, in L% ad CCCIV immaculatam ferro, praecipue summus temperatus (80-150 ° C) aut acidic environments.

Inhibitionis intergranular corrosio per nickel elementa

Et etiam de Nickel (ni) (E.G., VIII% -10.5% ni in CCCIV immaculatam ferro) stabilizes Austenitic structuram, reducendo ad praecipitatio de chromium carbides (crusc₆) ad frumenti terminos et ita vitandum intergrams. Hoc proprium est crucial in altus-temperatus aut acidic environments, significantly extendendo ministerium vita immaculatam ferro fores.

II. Superficiem curatio processibus: corporalis supplementi et eget coatings

Synergistic effectum mechanica texturing et eget etching

Per Sandblasting aut mechanica texiting processus, a microscopic asperitas (Ra 0.8-1.6μm) est creatus in immaculatam ferro superficiem, enhancing adhaesionem subsequent coatings et reducendo pulveris. Exempli gratia, in electronic bluarrooms, pulvis residuum a textured immaculatam ferro fores est XL% inferior quam in speculo-polita fores.

Dual praesidium corrosionis repugnans coatings

Epoxy resinae vel polyester pulveris spraying technology est ad formare a 0,05-.1mm densissima tutela iacuit in immacretur ferro superficiem. Haec coating exhibet optimum acidum et alkali resistentia (E.G., non mutat post XXIV horas in X% sulphuric acidum) et potest resistere D horas sal imbre testing (ISO (IX) CCXXVII). Praeterea, Nano-Titanium dioxide (tio₂) in coating enables photocatalytic auto-Purgato, longius reducing corrosio metus.

III. Structural Design: Integration de signationing et anti-permeability Optimization

Multi-gradu praesidio trium dimensional signantes systems

Cleanroom fores utor Silicone Flexilis Sigillis (Litus A60-70 duritia) et ostium tabulae ad formare airtight signacula, combined cum automatic elevatio vergit ad imo (descendendo altitudinis maior quam 0.3μ. In pharmaceutical bluarooms, hoc consilio reduces aeris leakage rates (later) ad sub 0.01cfm / ft² (ISO 14644-4 Latin).

ROSIO-repugnans consilio Weld-liberum compagibus

Per laser Welding aut Argon Arcus Welding technology, seamless hospites inter portam tabulata et tabulas sunt effectum, vitando intergranular et weld corrosio fecit a traditional welding. Exempli gratia, in Siconductor tutum, ministerium vitae laser-welded fores est 3-5 temporibus diutius quam conventionally welded ones.

IV. Environmental Adaptability: perficientur retention in extrema condiciones

Antioxidant facultatem in altus-temperatus et summus humiditas environments

In environments of 60°C and 90%RH humidity, the annual growth rate of the oxide film thickness on stainless steel doors is below 0.05μm, far lower than ordinary carbon steel (0.5-1μm annual growth rate). Hoc facit idoneam ad industries ut Biopharmaceuticals et cibum processus, ubi 湿热灭菌 (umidum calor sterilitate) environments prevalent.

ROSIO resistentia fortis acidum alkali ambitus

In simulata experimenta, 316L Aliquam ferro ostia ostendit non visibilia corrosio vestigia et missa damnum rate infra 0.05% post LXXII horis immersionem in X% sulphuric et X% sodium hydroxide solutions, demonstrando et electroplating.

VI. Application sem verificationis: Industry casibus et technica parametri

PHARMACEUTICAL Industry: Corrosion Protection in API productio environments

In Active Pharmaceutical Ingredient (API) productio, immaculatam ferro fores resistere corrosio ex organicum solvents (E.G., Methanol, acetonitrile) et acidic. Exempli gratia, a Biopharmaceutical Company reducitur apparatu Sustentacionem constat per LX% et downtime debitum ad corrosio per LXXX% post adoptando 316L immaculatam ferro fores.

Semiconductor industria, mundicia Fides in CMP processibus

In eget mechanica Polishing (CMP) processibus, immaculatam ferro fores oportet sustinere

Mors Purgato solutions quibus ammonia aqua et hydrogenii peroxide. Experimenta ostendere quod immaculatam ferro fores cum PVD coating technology exhibit superficiem asperitas mutationes infra 0.01μm post MM horas in CMP environments.

Food Industry: Compatibility cum CIP Systems

In mundum-in-place (CIP) systems ad lacticiniis et cervisia industries, immaculatam ferro ferro ferro pati CXXI ° C summus temperatus et summus pressura vapor et alterna I% sodium hydroxide solution rinses et alterna. A dairy incidents reducitur microbial contaminationem incidents per XCV% ex ostium corrosio post exsequendam.

VII. Long-term stabilitas et sustentationem oeconomia

Material senescit rate et lifespan praedictionem

Secundum ASTM G1-03 Signa, annua corrosio rate of CCCIV immaculatam ferro in tulkroom environments est infra 0.001mm / anno, cum speculativa ministerium vitae super L annis. Combined cum iusto tutela (E.G .: Sigillum inspectionem omnis VI menses, coating integritas reprehendo annuatim), in ipsa ministerium vitae potest extendere ad LXXX annis.

Vita Cost Cost (LCC) Analysis

Per a X-anno cycle, cum initial sumptus de immaculatam ferro fores est 2-3 temporibus, ut de Ordinarius ipsum Carbon ferro fores, sustentacionem costs sunt reducuntur per LXX% et replacement frequency a LXXX%, unde in XL% -60% decrementum in totalis costs.